Optimize volume of cylinder while maintaining surface area Free (1)

Optimize volume of cylinder while maintaining surface area

In this project, we are going to take the measurements of an existing tuna can and find the existing volume. We will then be using algebra and calculus, as well as graphing, to find the new measurements of an optimized tuna can, one that will hold more product, but without changing the surface area of the can.

The idea is to maintain the surface area of the material being used so as to keep the cost of production unchanged, but allowing the manufacturer of the tuna to add more product within the can, if they wish to do so.

Tuna Can

Measurements taken

Height: 4.1 cm

Circumference: 27.2 cm

① Find the radius of the tuna can using the circumference

② Current Volume of the tuna can

③ Surface Area of the tuna Can

Left-Aligned MathML

math {

display: block;

margin-left: 0;

color: #0F9ED5; /* Setting the color as specified in mathcolor */

}

④ Use the surface area equation and rewrite it so we have h in terms of r.

Subtract 2πr2 on both sides

Divide both sides by 2πr to solve for h

⑤ Write the equation of the Volume of the tuna can in terms of r only, by substituting h with the expression obtained in step ④ above.

Rewriting the above equations in terms of x

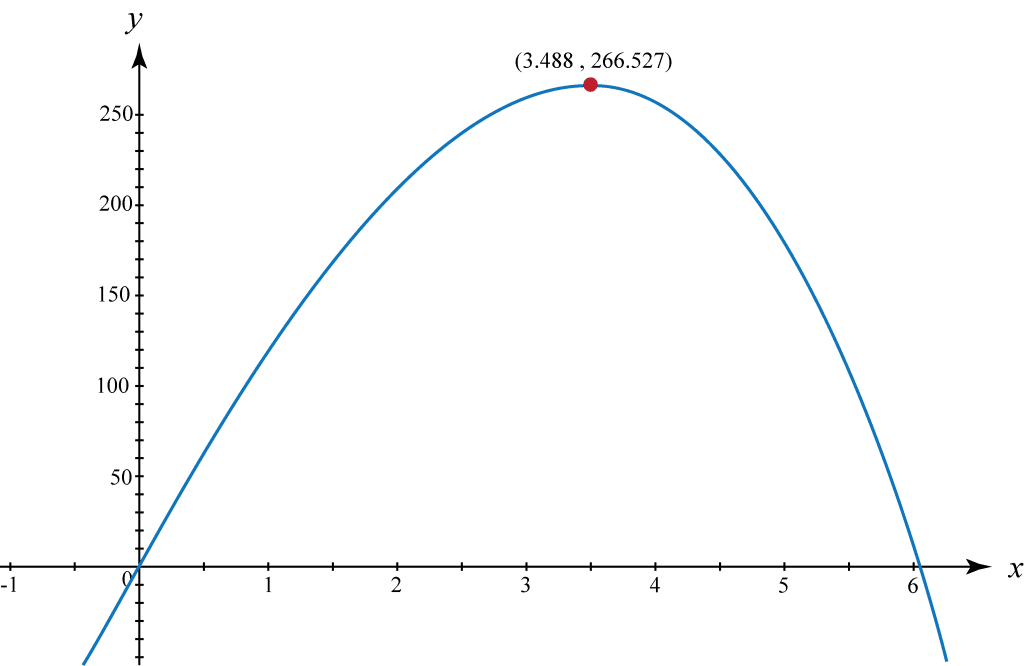

⑥ Graph the volume equation on your GDC or desmos.com

⑦ Finding the x-value (the radius) that maximizes the volume by taking the derivative of V(x), and setting V ' (x) = 0,

Setting V ' (x) = 0,

Divide both sides by - 3π

⑧ Substitute the value of x = 3.488 cm found in step ⑦ into the equation found in step ④ to find the height. This value is the radius, r, of the tuna can.

⑨ Substitute x = 3.488 cm found in step ⑦ into the volume equation to find the maximum volume.

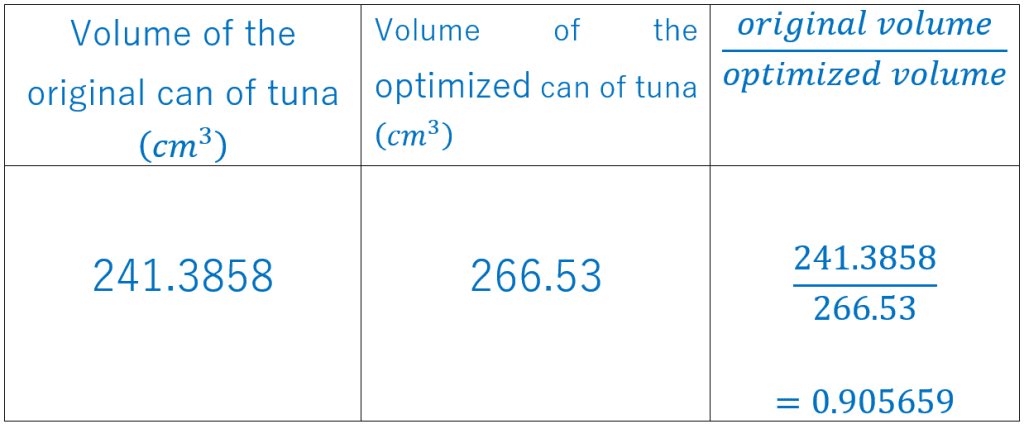

⑩ We will now compare the volumes of the optimized tuna can with the original tuna can by dividing the existing volume with the existing volume and getting a percentage value.

The result above shows a 90.57% optimized tuna can. This means that the existing tuna can, with a volume equal to 90.57% of the optimized tuna can, can have its volume increased to hold more tuna whilst maintaining the same surface area, so as to not increase the cost of material used in the production of the tuna can.

The optimized tuna can will have

The following measurements:

Height: 6.975 cm

Radius: 3.488 cm

Applications of Optimizing the Volume of a Cylinder While Maintaining Surface Area

Optimizing the volume of a cylinder while maintaining its surface area has several practical applications across various fields. Here are some key examples:Optimize Volume Of Cylinder

1. Packaging and Manufacturing

Container Design: In the packaging industry, optimizing the volume of cylindrical containers (like cans and bottles) while maintaining a specific surface area helps minimize material usage and costs while maximizing storage capacity. This is crucial for both economic and environmental reasons.Optimize Volume Of Cylinder

Efficient Use of Materials: Manufacturers aim to design containers that use the least amount of material for a given volume, reducing waste and production costs. This is particularly important for products such as food, beverages, and pharmaceuticals.Optimize Volume Of Cylinder

2. Engineering

Storage Tanks: Engineers design storage tanks for liquids (such as water, oil, and chemicals) with optimal volume while maintaining a fixed surface area to ensure structural integrity and cost efficiency. This is vital in industries such as oil and gas, water treatment, and chemical processing.Optimize Volume Of Cylinder

Heat Exchangers: In thermal engineering, the optimization of cylindrical components in heat exchangers can improve efficiency. Maintaining a fixed surface area while optimizing volume can lead to better thermal performance and reduced material costs.Optimize Volume Of Cylinder

3. Environmental Science

- Waste Management: Optimizing the volume of cylindrical waste containers (like bins and tanks) while maintaining a specific surface area can help in designing more efficient waste storage solutions. This is essential for waste management and recycling programs.Optimize Volume Of Cylinder

4. Food and Beverage Industry

Maximizing Product Storage: Beverage companies often optimize the volume of cylindrical containers (like soda cans) to maximize the amount of product they can store and transport while maintaining a fixed surface area to keep production costs low and ensure stackability.Optimize Volume Of Cylinder

Efficient Transportation: Optimized container designs lead to more efficient use of space during transportation, reducing the number of trips needed and, consequently, the carbon footprint.Optimize Volume Of Cylinder

5. Pharmaceuticals

- Pill Bottles and Vials: Pharmaceutical companies optimize the volume of cylindrical pill bottles and vials to ensure they contain the maximum number of pills or the maximum volume of liquid medicine while using minimal material. This ensures cost-effective production and ease of handling.Optimize Volume Of Cylinder

Recent Posts

- Geometry Regents Score Calculator 2026 | Predict Your Grade

- Algebra 2 Regents Score Calculator (2025 NY Exam Tool)

- Algebra 1 Regents Score Calculator (NY Regents Estimator)

- PreACT® Score Calculator (2025 Raw-to-Scaled Estimator)

- ACT® Score Calculator (2025 Raw-to-Scaled Score Tool)

- PSAT® Score Calculator (2025 Digital Exam Estimator Tool)

- AP® Music Theory Score Calculator (2025 Exam Estimator)

- AP® Art History Score Calculator (2025 Exam Estimator)

- AP® Spanish Literature Score Calculator (2025 Exam Tool)

- AP® Spanish Language Score Calculator (2025 Exam Tool)

- AP® Latin Score Calculator (2025 Exam Scoring Tool)

- AP® German Language Score Calculator (2025 Exam Tool)

- AP® French Language Score Calculator (2025 Exam Tool)

- AP® English Literature Score Calculator (2025 Exam Tool)

- AP® English Language Score Calculator (2025 Exam Tool)

Choose Topic

- ACT (17)

- AP (20)

- AP Art and Design (5)

- AP Chemistry (1)

- AP Physics 1 (1)

- AP Psychology (2025) (1)

- AP Score Calculators (35)

- AQA (5)

- Artificial intelligence (AI) (2)

- Banking and Finance (6)

- Biology (13)

- Business Ideas (68)

- Calculator (73)

- ChatGPT (1)

- Chemistry (3)

- Colleges Rankings (48)

- Computer Science (4)

- Conversion Tools (137)

- Cosmetic Procedures (50)

- Cryptocurrency (49)

- Digital SAT (3)

- Disease (393)

- Edexcel (4)

- English (1)

- Environmental Science (2)

- Etiology (7)

- Exam Updates (7)

- Finance (129)

- Fitness & Wellness (164)

- Free Learning Resources (208)

- GCSE (1)

- General Guides (40)

- Health (107)

- History and Social Sciences (152)

- IB (9)

- IGCSE (1)

- Image Converters (3)

- IMF (10)

- Math (44)

- Mental Health (58)

- News (9)

- OCR (1)

- Past Papers (450)

- Physics (5)

- Research Study (6)

- SAT (39)

- Schools (3)

- Sciences (1)

- Short Notes (5)

- Study Guides (28)

- Syllabus (19)

- Tools (1)

- Tutoring (1)

- What is? (312)

Recent Comments

The Collatz Conjecture: Current Research and Approaches

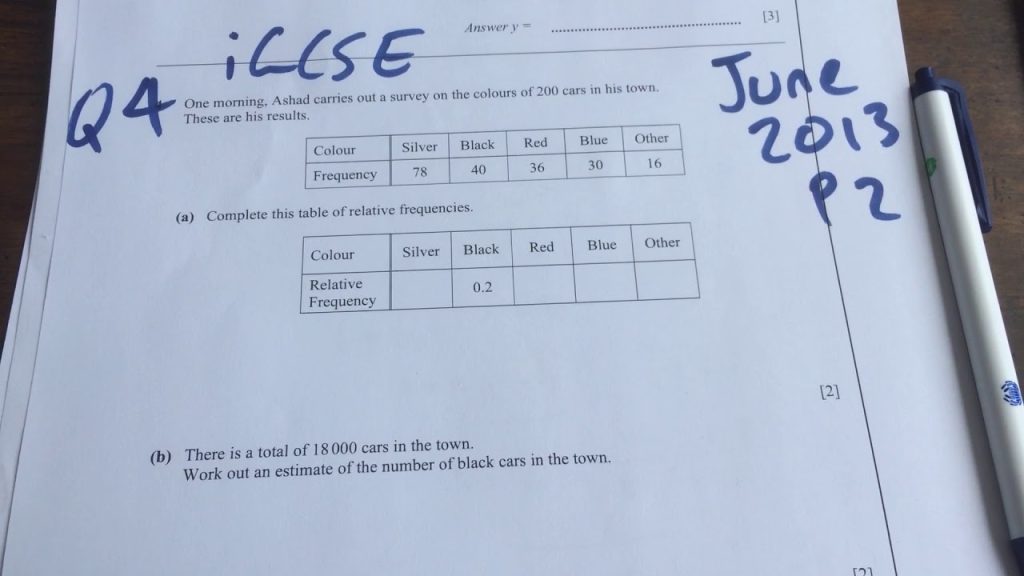

Relative Frequency Formula: Everything You Need to Know

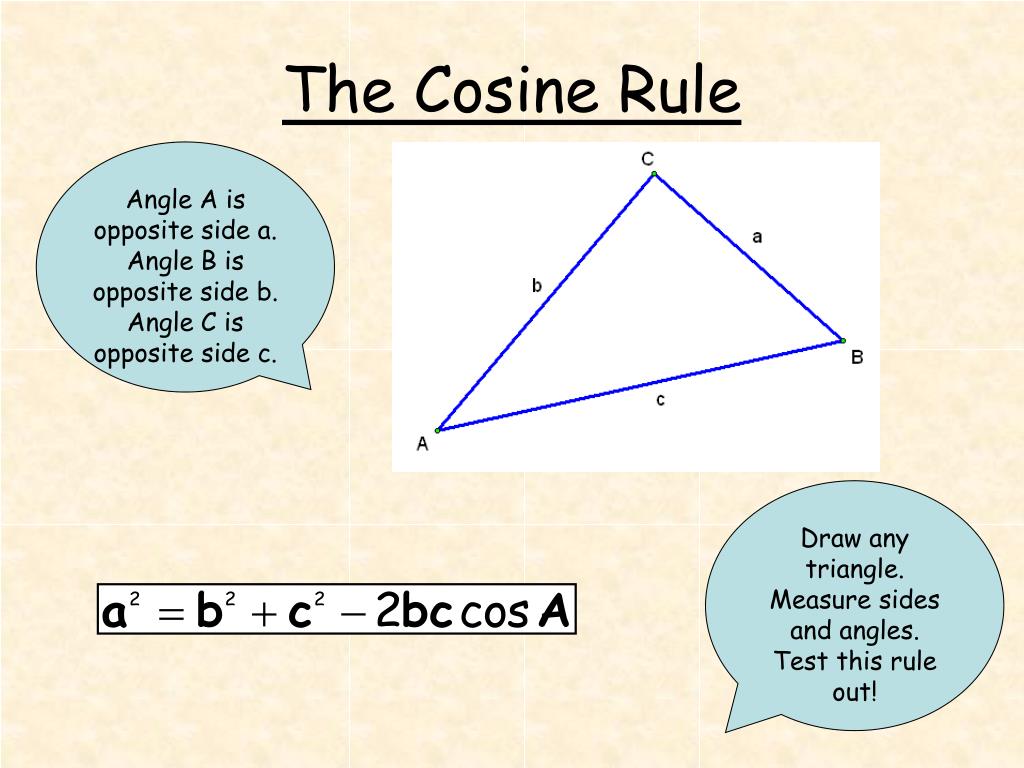

What is Cosine Law: Everything You Need to Know

Guide to Calculating Fractions: Concepts, Conversions, and Practical Applications

Word to JPEG – Convert Word files to JPEG Images Online

WebP to JPEG – Convert WebP to JPEG

HEIC to JPG – Convert HEIC Images to JPEG Format