A capacitor has large number of specifications and characteristics. By observing the information printed on the body of a capacitor, we can understand very well about the characteristics of a capacitor. But some capacitors have colors or numeric codes on their body, due to this it is difficult to understand about characteristics. Each type or family of capacitor has its own set of characteristics and identification system. Some capacitors identification systems are easy to understand their characteristics and others use misleading symbols, letters and colors.

To understand the characteristics of a particular capacitor easily, first find out the capacitor family whether it is ceramic, plastic, film or electrolytic and from that it is easy to identify the characteristics. Even though capacitors have same capacitance value they may have different working voltages. If you use a capacitor which has low working voltage in place of a capacitor which has high working voltage then the increased voltage may damage the low voltage capacitor even though both capacitors have same capacitance.

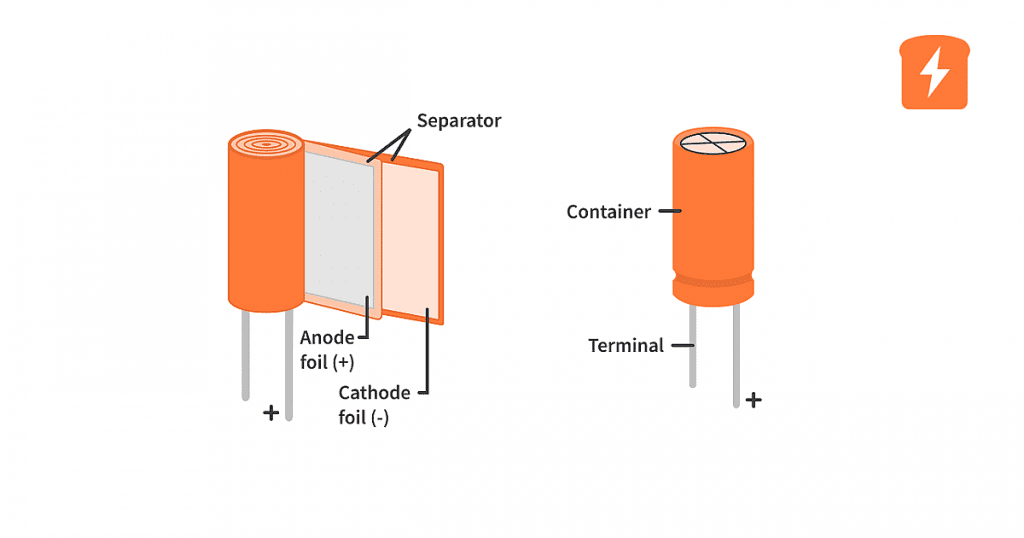

Already we know that electrolytic capacitor has polarities, so while connecting the electrolytic capacitor in the circuit, positive terminal must connect to the positive connection and negative terminal of capacitor to negative connection otherwise the capacitor may damage. So it is always better to replace the damaged or old capacitor in the circuit with the new one which has same characteristics. The figure below figure shows the characteristics of a capacitor.

Figure 1.Capacitor Characteristics

Capacitor Characteristics

A capacitor comes with a set of characteristics. All these characteristics can be found in datasheets that are provided by capacitor manufacturers. Now let us discuss some of them.

Nominal Capacitance (C)

One of the most important one among all capacitor characteristics is the nominal capacitance (C) of a capacitor. This nominal capacitance value is generally measured in pico-farads (pF), nano-farads (nF) or micro-farads (uF), and this value is indicated with colors, numbers or letters on the body of a capacitor. This nominal capacitance value, which is printed on the side of a capacitor body, is not necessary to equal to its actual value.

The nominal capacitance value may change with working temperatures and with the circuit frequency. These nominal values are as low as one pico-farad (1pF) for smaller ceramic capacitors and as high as one farad (1F) for electrolytic capacitors. All capacitors have a tolerance rating that ranges from -20% to +80%.

Working Voltage (WV)

The working voltage is one more important characteristic of all capacitor characteristics. The maximum amount of voltage which is applied to a capacitor without failure during its working life is called as working voltage (WV). This working voltage is expressed in terms of DC and also it is printed on the body of a capacitor.

Generally working voltage which is printed on the body of a capacitor , refers its DC voltage but not its AC voltage , because the AC voltage is in its rms value. So capacitor working voltage must be greater than the 1.414 (Vm = Vrms x√2) times of its actual AC value to apply AC voltage to the capacitor. This specified DC working voltage of a capacitor(WV-DC) is valid only within in a certain temperature range, such as -300C to +700C. If you apply a DC or AC voltage which is greater than the working voltage of a capacitor then the capacitor may damage.

The working voltages which are commonly printed on the body of a capacitor are 10V, 16V,25V, 35V, 50V, 63V, 100V, 160V, 250V, 400V and also 1000V. All the capacitors will have a longer working life if they operated within their rated voltage values and in a cool environment.

Tolerance (±%)

Tolerance is the permissible relative deviation of the capacitance from the rated value, which is expressed in per cent. Like resistors, the tolerance value for capacitor also exists in either plus or minus values. This tolerance value is generally measured in either pico-farads (+/-pF) for low value capacitors which are less than 100pF or in percentages (+/-%) for higher value capacitors, which are greater than 100pF.

The tolerance value of a capacitor is measured at a temperature of +20°C and it is valid only at the time of its delivery. If a capacitor may be used after a longer period of storage then the tolerance value will increase, but according to the standard specifications, this value will not exceed twice the value which is measured at the time of its delivery. The delivery tolerances usually for wound capacitors are +/-(1%,2.5%,5%,10%,20%). The very general tolerance values variation for capacitors is 5% or 10%, and this is rated as low as +/-1% for plastic capacitors.

Leakage Current (LC)

All dielectric materials which are used in the capacitors to separate the metal plates of capacitors are not perfect insulators. They allow the small amount of current, such as leakage current to flows through it. This effect is because of the high powerful electric field which is formed by the charge particles on the plates of a capacitor when supply voltage (V) is applied to it.

The leakage current of a capacitor is a small amount of DC current which is in nano-amps (nA). This is because of the flowing of electrons through the dielectric material or around its edges and also by discharging it overtime when the power supply removed.

Leakage current is defined as transferring of unwanted energy from one circuit to another circuit. One more definition is the leakage current is a current when ideal current of the circuit is zero. Capacitors leakage current is a considerable factor in amplifier coupling circuits and in power supply circuits.

The leakage current is very low in film or foil type capacitors and it is very high (5-20 uA per uF) in electrolytic (tantalum and aluminum) type capacitors, where their capacitance values are also high.

Working Temperature

The capacitance value of a capacitor varies with the changes in temperature which is surrounded the capacitor. Because the changes in temperature, causes to change in the properties of the dielectric. Working Temperature is the temperature of a capacitor which operates with nominal voltage ratings. The general working temperatures range for most capacitors is -30°C to +125°C. In plastic type capacitors this temperature value is not more than +700C.

The capacitance value of a capacitor may change, if air or the surrounding temperature of a capacitor is too cool or too hot. These changes in temperature will cause to affect the actual circuit operation and also damage the other components in that circuit. I think it is not a simple thing to keep the temperatures stable to avoid capacitors from frying.

The liquids within the dielectric can be lost to evaporation especially in electrolytic capacitors (aluminum electrolytic capacitors) when they will operate at high temperatures (over +850C)and also the body of the capacitor would become damaged due to the leakage current and internal pressure. And also the electrolytic capacitors cannot be used at low temperatures, such as below -100C.

Temperature Coefficient

The temperature coefficient (TC) of a capacitor describes the maximum change in the capacitance value with a specified temperature range. Generally the capacitance value which is printed on the body of a capacitor is measured with the reference of temperature 250C and also the TC of a capacitor which is mentioned in the datasheet must be considered for the applications which are operated below or above this temperature. Generally the temperature coefficient is expressed in the units of parts per million per degree centigrade (PPM/0C) or as a percent change with a particular range of temperatures.

Some capacitors are linear (class 1 capacitors), these are highly stable with temperatures; such capacitors have a zero temperature coefficient. Generally Mica or Polyester capacitors are examples for the Class 1 capacitors. TC specification for class 1 capacitors will always specifies the capacitance change in parts per million (PPM) per degrees centigrade.

Some capacitors are non linear (class 2 capacitors), these capacitors temperatures are not stable like class1 capacitors, and their capacitance values will increase by increasing the temperature values, Hence these capacitors gives a positive temperature coefficient. The main advantage of the class 2 capacitors is their volumetric efficiency. These capacitors are mainly used in the applications where high capacitance values are required, while stability and quality factor with temperatures are not main factors to consider. The Temperature Coefficient (TC) of class 2 capacitors is expressed directly in percentage. One of the useful applications of temperature coefficient of capacitors is to use them to cancel out the effect of temperature on other components within a circuit such as resistors or inductors etc.

Polarization

Generally the capacitor polarization belongs to the electrolytic type capacitors, such as aluminum type and tantalum type of capacitors. Majority of the electrolytic capacitors are polarized, that is it needs correct polarity when supply voltage is connecting to the capacitor terminals, such as positive (+ve) terminal to positive (+ve) connection and negative (-ve) to negative (-ve) connection.

The oxide layer inside the capacitor may broken by incorrect polarization, this causes to flow of high currents through the device. As a result capacitor damages as mentioned earlier. To prevent incorrect polarization the majority of electrolytic capacitors have arrows or black stripe or band or chevrons on one side of their body to denote their negative (-ve) terminals as shown in the below figure.

Polarized capacitors have large leakage currents if their supply voltage is inverted. The leakage current in polarized capacitors distort the signal, over heats the capacitor and finally destroys. The basic reason to use polarized capacitors is their less cost than non-polarized capacitors of same voltage ratings and same capacitance values. Basically the polarized capacitors are available in the units of micro-farads, such as 1uF, 10uF etc.

Figure 2.Polarization of the Capacitor

Equivalent Series Resistance (ESR)

The equivalent series resistance (ESR) of a capacitor is defined as the AC impedance of a capacitor when it used at very high frequencies and also with the consideration of dielectric resistance. Both the DC resistance of dielectric and the capacitor plate’s resistance are measured at a particular temperatures and frequency.

ESR acts like a resistor in series with a capacitor. The ESR of a capacitor is the rating of its quality. We know that theoretically a perfect capacitor is lossless and also have the ESR value zero. Often this resistance (ESR)causes to failures in the capacitor circuits.

The Effects of Equivalent Series Resistance

The equivalent series resistance (ESR) of the output capacitor in the circuit causes to affect the performance of the device. And also the ESR may reduce the supply voltage of a capacitor. The ESR is quite opposite to the insulation resistance of a capacitor which is presented as pure resistance in parallel with the capacitor in some type of capacitors. An ideal capacitor has only its capacitance and ESR value is very less (less than 0.1Ω).

If the dielectric thickness increases then the ESR will increase. If the surface area of the plate increases then the ESR value will go down. To calculate capacitor’s ESR, we requires something other than a standard capacitor meter such as ESR meter. If the capacitor meter is a handy device then it will not detect capacitor failures which increase the ESR value.

In a non-electrolytic capacitor or a capacitor with solid electrolyte the metallic resistance of leads, electrodes and losses in the dielectric are causes to ESR. Generally the ESR values for ceramic capacitors are in between 0.01 to0.1 ohms. Aluminum and tantalum electrolytic capacitors with non solid electrolyte have very high ESR values, such as several ohms. A main problem with aluminum electrolytic capacitors is that, the circuit components will damage if the ESR values of the capacitors which are used in that circuit increases over time in the operation.

Generally the ESR values are less for polymer capacitors than electrolytic (wet) capacitors of same value. Thus the polymer capacitors can handle the higher ripple currents. A capacitor can be used as a filter which having a very low ESR ratings. Capacitors have the ability of storing the electrical charge even though the charging current is not flowing through it. The capacitors used in the televisions, photo flashes and capacitor banks are generally of electrolytic type capacitors. According to the thumb rule the leads of large value capacitors are need to never touch after power supply was removed.

1. What is Nominal Capacitance (C) in a Capacitor?

Nominal capacitance (C) refers to the stated value of capacitance for a capacitor, typically measured in pico-farads (pF), nano-farads (nF), or micro-farads (μF). This value, marked on the body of the capacitor, is an approximation and can vary slightly with temperature and circuit frequency. Capacitors can range from small values (1 pF) to large values (1 F), with tolerance ratings ranging from -20% to +80%.

2. What is the Working Voltage (WV) of a Capacitor?

The working voltage (WV) is the maximum voltage a capacitor can safely handle without failure. It is typically expressed in terms of DC voltage and is printed on the capacitor. When using AC voltage, the working voltage must be at least 1.414 times the AC value due to the relationship between RMS and peak voltages. Exceeding the working voltage can lead to capacitor failure.

3. What is the Tolerance of a Capacitor?

Tolerance represents the allowable deviation of a capacitor’s actual capacitance value from its nominal value. It is often expressed as a percentage (e.g., ±5%). Tolerance is crucial when precise capacitance is required. Capacitors typically have tolerances ranging from ±1% to ±20%, depending on the type and application.

4. What is Leakage Current (LC) in a Capacitor?

Leakage current refers to the small amount of current that flows through a capacitor due to imperfect insulation in the dielectric material. This current is measured in nano-amperes (nA) and can cause energy loss in circuits. Electrolytic capacitors tend to have higher leakage currents compared to film or foil capacitors.

5. How Does Temperature Affect Capacitors?

The capacitance value of a capacitor changes with temperature because the properties of the dielectric material are temperature-dependent. Most capacitors have a working temperature range, typically from -30°C to +125°C. Extreme temperatures can cause damage, particularly in electrolytic capacitors, where high temperatures can lead to leakage and reduced lifespan.

6. What is the Temperature Coefficient (TC) of a Capacitor?

The temperature coefficient (TC) indicates how the capacitance value changes with temperature. It is expressed in parts per million per degree Celsius (PPM/°C). Capacitors with a zero or low TC are more stable with temperature changes (e.g., Mica or Polyester capacitors). On the other hand, capacitors with positive TC values experience an increase in capacitance as temperature rises, which is common in class 2 capacitors.

7. What is Polarization in Capacitors?

Polarization refers to the requirement that certain capacitors, like electrolytic and tantalum types, must be installed with correct polarity. Reversing the polarity can damage the capacitor, causing leakage, overheating, or even failure. Polarized capacitors are marked with a negative sign on one terminal, indicating the correct orientation.

8. What is Equivalent Series Resistance (ESR)?

ESR is the resistance that appears in series with a capacitor when it is used in AC circuits. ESR is a measure of the quality of a capacitor, with lower values indicating better performance. High ESR can cause losses, reduce efficiency, and lead to heating and failure, particularly in power supply circuits. Polymer capacitors generally have lower ESR compared to electrolytic capacitors.

9. How Does ESR Affect Capacitor Performance?

The ESR of a capacitor can impact the performance of circuits, especially in high-frequency applications. High ESR can result in reduced voltage stability, loss of power, and increased heating. In power supply applications, high ESR can cause ripple currents to damage components. Low ESR capacitors, like polymer capacitors, are often preferred in such circuits.

10. What Happens if the Working Voltage is Exceeded in a Capacitor?

Exceeding the working voltage of a capacitor can lead to dielectric breakdown, capacitor damage, or even failure. This may result in leakage current, overheating, or, in extreme cases, capacitor rupture or explosion. It’s essential to choose a capacitor with a working voltage rating higher than the maximum voltage expected in the circuit.

11. What is the Impact of High Leakage Current in Electrolytic Capacitors?

Electrolytic capacitors, particularly those used in power supplies, often have higher leakage currents compared to other types. While this may not significantly impact low-frequency circuits, in high-frequency applications, excessive leakage current can cause distortion, affect signal quality, and reduce overall efficiency.

12. What is the Recommended Operating Temperature for Capacitors?

The recommended operating temperature for most capacitors typically ranges from -30°C to +125°C. However, each type of capacitor has a specified temperature range printed on its datasheet. It’s crucial to ensure that the temperature does not exceed the rated value to avoid capacitor failure, especially for electrolytic types, which may suffer from liquid evaporation at high temperatures.

13. How Can Capacitor Tolerance Impact Circuit Design?

Capacitor tolerance can significantly affect circuit performance, especially in applications requiring precise capacitance. High-tolerance capacitors (e.g., ±1%) are suitable for circuits where accuracy is critical, such as timing or signal processing circuits, while lower tolerance capacitors (e.g., ±20%) may be used in less critical applications.

14. What Are the Applications of Capacitors with High ESR?

Capacitors with high ESR are typically not suitable for high-frequency applications or circuits requiring low losses. However, they may still be used in power supply circuits where their higher ESR does not significantly impact performance, or in low-cost applications where precision is not as critical.

15. What is the Effect of Storage Time on Capacitor Tolerance?

Capacitors may experience a change in tolerance after prolonged storage. Typically, the tolerance will increase, but it should not exceed twice the original measured value. It’s important to check the capacitor’s condition after long-term storage before using it in a circuit to ensure its reliability.

16. How Does the Capacitance of a Capacitor Change with Temperature?

Capacitance generally decreases at higher temperatures for most capacitor types, especially for ceramic capacitors. This change in capacitance can affect the operation of a circuit, particularly in precision applications. Some capacitors are designed to be stable over a wider range of temperatures, while others may have more significant shifts.

17. Why is the Working Temperature of Electrolytic Capacitors Critical?

Electrolytic capacitors are particularly sensitive to temperature changes. At high temperatures (above 85°C), they are more prone to leakage, which can damage the capacitor and surrounding components. Low temperatures (below -10°C) can also cause electrolytic capacitors to fail, as the electrolyte becomes less conductive.

18. How Can Leakage Current Impact Amplifier Circuits?

In amplifier circuits, excessive leakage current can cause unwanted signal distortion, affecting the clarity and stability of the audio or RF signal. Capacitors with low leakage currents are crucial in coupling and decoupling applications to maintain signal integrity.

19. How Does the Dielectric Material Affect Capacitor Characteristics?

The dielectric material used in a capacitor impacts several characteristics, including capacitance, temperature coefficient, working voltage, and ESR. For example, ceramic dielectrics offer high capacitance in small sizes, while paper or aluminum electrolytics provide high energy storage but are more sensitive to temperature changes.

20. What Is the Role of Temperature Coefficient in Selecting Capacitors?

The temperature coefficient (TC) helps determine how much a capacitor’s capacitance will change with temperature. In applications where temperature stability is critical, capacitors with a low or zero TC, such as Mica capacitors, are preferred. For high capacitance applications where temperature stability is less of a concern, capacitors with a positive TC, such as Class 2 ceramics, may be suitable.

Other Post about Capacitors